|

Forth Contemporary Falcate Classical Guitar Build Blog:

17 Mar 2017

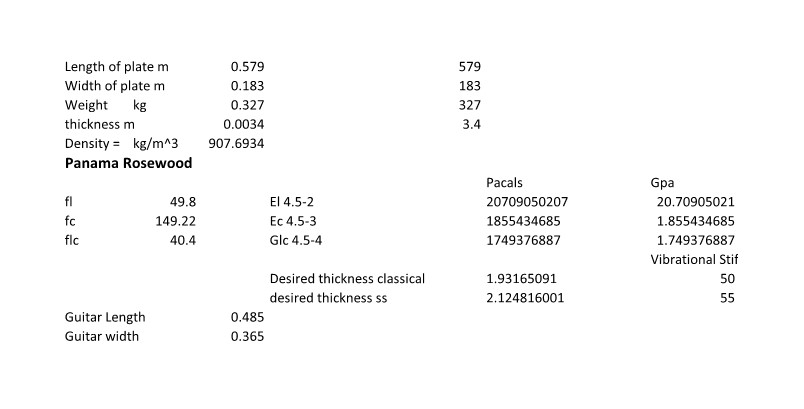

This is actually a restart of an earlier post I was going to make a Western Red Cedar Falcate, but have decided to make another using Lutz spruce with my Panama Rosewood back and side set. The Panama rosewood with is a real special set with great tonal quality. While tap testing even the cross grain tap made a wonderful sounding tone. Here are the tap test results. I joined it with a thin black fiber strip running up the center.

.jpg)

I bent the sides in a side bander and installed a heel block to make a bolt on blot off neck.

.jpg)

I cut out a bunch of 1.7 mm strips for solid linings. I have made them by just laminating them right to the rims. This time I decided to make the linings off of the guitar. I bent a strip of wood thicknessed like my sides, bent to shape of the rims. I used that strip and a half of a outside mold as the mole to laminate the strips into a solid lining. My though was that I could clean up the bottom of the linings with a round over router bit. Later it occured to me that I could cut inlets for the mass block and the side supports. I was happy about the way it cam together.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

I cut out a bunch of stock for back braces and used the 17.5 degree router bit to make the gable on top of the brace.

.jpg)

.jpg)

.jpg)

I laid out the braces cut the rebate in the center strips and used a couple of sessions to glue them to the back in a gobar deck.

.jpg)

.jpg)

.jpg)

.jpg)

I also did some of the layout and prep for the bolt on bolt off neck

THe only new thing was to rig up a finger chopper offer to make the cut of the scarf joint on the neck. It came out clean and square needing almost no work with a plane.

.jpg)

.jpg)

.jpg)

It glued up with no drama

.jpg)

.jpg)

I used a 4 mm strip to set the angle for the truss rod.

.jpg)

.jpg)

.jpg)

I have a fancy 24" radius bit that I used radius the fretboard.

.jpg)

I cut the frets and laminated on a 4 mm thick strip of mahogany to the underside of the fret board.

.jpg)

But foolish me I tapered the fretboard before I router the truss rod slot into the what will be the widge. So I cut it out with a scalpel and a chisel.

.jpg)

I also made the falcate braces laminating Lutz spruce strips that I bend on a hot pipe using molds I made for previous guitars

.jpg)

.jpg)

.jpg)

All caught up with the new blog.

18 Mar 2017

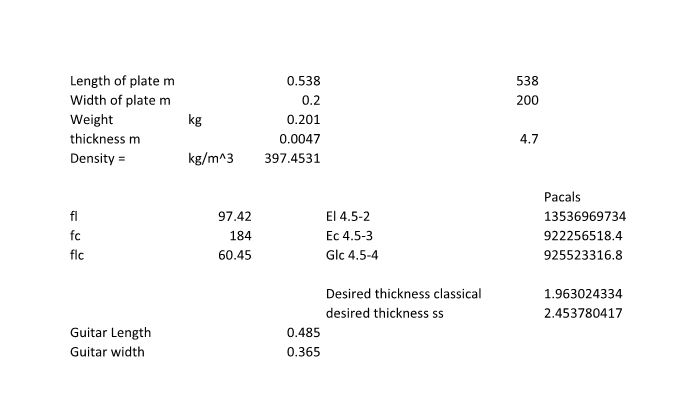

Up until this afternoon I have been deciding on a top. I had settled on a lutz top from Mario (Curly bear) that look good and had a good tap. But this morning digging through my tops I came upon a Carpathian Spruce top that I picked up at a Seattle Luthiers Org auction, from a classical builder. It had a great long lasting tap tone. I did the tap test for thickness and found it is one of the better tops I have tested. It is stiffer 13.5 vs. 12.7 GPa and less dense 397 vs 422 Kg/m^3

Just did a little today. I glued up the top and I have one side of the rims complete. I am mostly using hot hide glue. When I glued up the top I used both the stretched tape and my joining jig. The tape was probably enough and it was very quick to close to the joint before the glue gelled.

.jpg)

.jpg)

Hard to see now but I am using Advanced Shell Technology (AST) A4 kerfed linings. It is a little pricy but it bends in 4 directions so it is easy to follow the 3 meter radius of the back (really 10').

.jpg)

I have the linings and the side support strips in. The Book suggests running the side strips to the end of the rims on the back. Since I was using 4 mm strips instead of 6.5 mm I cut them short and capped them with a bit of the kerfed lining to keep the width of gluing service the same around the rims.

.jpg)

Here is how I cheat to make Classical looking rosettes with figured wood ring. I bought a bunch of russian rosettes with various types of purflings or end grain tile purflings. I choose one whos purflings went with the amboyna burl wood that I want to cut a ring out of. I install the bought rosette and then route out the center tiles. They come out clean because once you get close to the purflings the end grain squares that make the tiles just fly out. Leaving a clean purfling. Here is the process.

I joined the a couple of pieces of amboyna purl

.jpg)

Installed the classical rosette in a normal way. I draw out the lines and inch up on them.

.jpg)

.jpg)

.jpg)

Fits so I glue it on

.jpg)

I start in the center of the tiles and slowly work my way toward the purfling on each side until I have a clean channel.

.jpg)

.jpg)

Based on the real measurements of the channel I draw out the lines on my amboyna burl. Leaving the depth of the router the same depth I used to make the channel. Starting outside of the lines of the ring I work my way toward the line. When close I measure the rin to see how it will fit in the channel.

.jpg)

.jpg)

I then run the burl ring side down through my thickness sander until the ring drops out.

.jpg)

.jpg)

Great fit!

.jpg)

.jpg)

20 Mar 2017

Moving on I have the rim and the back ready, I have the top within .2 mm of final thickness. I always leave a bit because I always make some scratch to dent.

Here are some pictures from carving the back braces. I have shown my little 2 mm trimming jig before. Everytime I use it I can not get over how much time I saved over getting close and measuring. When I am finished, all of the brace ends are the same so I can also route all of the pockets in the linings without adjusting the router depth. I still need to spend some quality time on the inside with scrapers and sandpaper.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

After I thickness the top I glued on a sound hole doubler, not sure why I did not take a picture. With the sound hole doubler on I was able to route the sound hole. I never route through, leave the plug in long into the build. With the top sanded I covered it with 5 mill mylar.

.jpg)

.jpg)

.jpg)

.jpg)

25 Mar 2017

I prepped the top to start the bracing, This time I decided to take a couple of passes epoxying the brace to the top. I started out with the falcate braces, I glued them on in a 32' radius dish in my go bar deck. The layup is the top, 4K 5.7oz carbon fiber tow and them the brace. I do not have a picture, but the next day I planed the braces to the target heights with a block plane and profiled them with a small block plane and a bit of chisel work The braces are 10 mm and 7.5 mm at the most.

.jpg)

.jpg)

I prepared the rest of the braces and epoxyed them to the top

.jpg)

.jpg)

I profiled those braces and put a 4K 5.7oz carbon fiber tow on the top of all the braces. I do this in the radius dish to set the radius into the top.

.jpg)

While waiting for the epoxy to cure I cut the neck tenon out on a table saw.

.jpg)

.jpg)

I put a radius on just the outside edge of the transverse brace leaving the center flat. I marked out where the falcate and sound hole braces cross into the transverse brace and cut out the channels using a razor saw and a chisel

.jpg)

.jpg)

.jpg)

.jpg)

I epoxyed the transverse brace down, being lazy I left out the CF. It is a big brace. Under the top I have a caul that matches the radius and flat spot on the brace.

.jpg)

I profiled the brace.

.jpg)

Getting ready to routed the notches in the top linings.

.jpg)

I have a bunch of glue clean up to do; after that I am ready to close the box.

.jpg)

25 Mar 2017

I did do a small trip but I have also got the box closed with the bindings and purflings on.

Shaping in the ends in a drum sander sounds like a good way to go. I got away from preshaping my braces when I started to use a vacuum box, the change in height in such a short distance did not really work with my vacuum box. Although for this guitar I used a gobar deck. I have my handy dandy jig that I use to both size the brace ends and protect the back.

.jpg)

I need to make a bunch of check lists for some of the major assembly steps. Like before closing the box: [i]Install the end-graph ___[/i]. I happily prepared a batch of hot hide glue and glued the back on. Somehow I managed to get the hot hide glue on and the back clamped before the glue gelled.

.jpg)

Whoops no end-graph. I see a lot of builders who cut the rebate after closing. I hate to because I cut into what was to be the finished part of the top once. So before gluing on the top I did cut the rebate and install an ebony and maple strip graph. I used a scalpel to cut mark and then cut out the outline of the graph and I cleared the rebate with a chisel. And yes I am messy with hide glue as well. It does wipe off with some water.

.jpg)

.jpg)

.jpg)

Again using hot hide glue I glued the top on.

.jpg)

Preparing for bindings I glued on a maple purfling strip with to some ebony bindings. I used titebond III as I hear it was better with heat.

.jpg)

I use my inflatable spindle sander to even up the sides. Truth be told I did a bunch of the leveling of the sides with a scraper. I do this before binding to assure that I have a smooth level surface for the bindings machine bearing to ride index on.

.jpg)

To allow me to join the maple purfling strips I taped a maple purling strip to the back over the end graph. This strip will force the router to lift leaving a purfling strip (and a tape thickness) of the end wedge above the binding rebate.

.jpg)

My binding machine note shown in the pictures is a Fleishman Binding Machine [url]http://www.bluescreekguitars.com/shop/index.php?main_page=product_info&cPath=43&products_id=140[/url]. Instead of using bits with bearing for the depth I installed a Luthier Tool Company binding cutter head on my router. [url]http://www.luthiertool.com/self-aligning-binding-cutter.html[/url]

Once I cut the binding channel I cleaned up the end graph area with a hand binding channel cutter.

.jpg)

I fit the binding, including cutting away a portion on the purfling on the end wedge end and glued on the binding with hot hide glue.

.jpg)

.jpg)

Same process for the top, except that the top had three purfling stripts (black, rosewood, black). Because of the additional hassle with the purflings strips I used fish glue. Sorry I do not have a lot of pictures, you have seen me with glue. Fish glue is very messy. My process as to coat the purflings with fish glue and force them together off the guitar. Using about 4 or five strips of tape I installed them on the purfling ledge, making sure they were cleanly on the ledge. I then then back and painted the binding channel with fish glue and installed the binding. The fish glue gets so tacky I was able to remove the strips of tape that I use to install the purflings. Also fish glue has such a long open time that there was no issue with installing the binding and pulling the binding and purflings tight with binding and fiber tape.

.jpg)

.jpg)

.jpg)

.jpg)

I did a bit more work today on the neck while the binding are clearing. Fish glue takes a bit to cure. I used a bandsaw and a belt sanding to do the initial shaping of the heel.

.jpg)

.jpg)

.jpg) Next

Next

|

|

|

|

|