Kenneth Michael Guitars LLC

| “Guitar Binding Channel Routing System” ™ v2 plus top and back overhang trimmer |

The “Guitar Binding Channel Routing System” © is a turnkey tool that is ready to work

using your sharp standard 1/4" straight bit. A down-spiral bit can also be used, up-

spiral bits are not recommended. The package includes Trim Router with sealed ball

bearing spindle and an easy to use geared height adjuster, Wood grain Melamine

table base with raised platen and infinite depth “MICRO” adjuster, and the “GBC

shuttle”©. NOTE THAT THE ABILITY TO EASILY CHANNEL CONTOURED TOPS AND

BACKS WAS THE "NUMBER ONE" DESIGN CRITERIA OF THIS SYSTEM.

This product design was developed over a number of years. We have purchased or

built virtually every binding/purfling gadget and tool out there including the one with the

router mounted on the sliding vertical stand. In our opinion none of them are very user

friendly. The inspiration for this machine came while observing the crafts persons at the

CF Martin Factory. These individuals effortlessly routed the top and back binding

rebates in just a few minutes. Although skilled, it was obvious that they did not have a

fear that their machines were going to initiate an improper cut. Also, they were in total

control of the process and the guitar body. The same is true of the operation at the

Taylor factory.

The following sets this machine apart from all others:

· Cost – Ours is reasonably affordable where as the complicated, not so user

friendly, West coast and Ohio style overhead machine with cutters is almost $700 and it

is still unable to cut custom grooves or handle slightly over or under size binding and

purflings!!!

· Router Bit – No fancy expensive bits or bearing size math calculations required!

All that is needed is a sharp 1/4" HSS (high speed steel) straight bit. Down-spiral bits

yield great results--- up-spiral bits or end mills are not recommended.

· Setup – Infinite height and depth adjustment in about 2 minutes – No Bit or

bearing changes – No carriage to adjust. We route D’s 000’s and J200 Jumbos using

the same bit settings. Simply put the body on the “GBC Shuttle” and start.

· Control – The cutting bit is directly in front of the operator and guitar is easily

and precisely guided on the platen using the “GBC Shuttle” The “GBC Shuttle” while

eloquently simple in design, provides for variable height. In addition it automatically and

gently handles tapered sides as well as top and back radius contours

· Quality – The captive bit feature virtually eliminates the possibility of damage

caused by presenting the body at the wrong angle to the bit or vise versa

· Dust Collection – We are not aware of any other machine with this feature.

Note: photos are file copies of our prototype machine.

using your sharp standard 1/4" straight bit. A down-spiral bit can also be used, up-

spiral bits are not recommended. The package includes Trim Router with sealed ball

bearing spindle and an easy to use geared height adjuster, Wood grain Melamine

table base with raised platen and infinite depth “MICRO” adjuster, and the “GBC

shuttle”©. NOTE THAT THE ABILITY TO EASILY CHANNEL CONTOURED TOPS AND

BACKS WAS THE "NUMBER ONE" DESIGN CRITERIA OF THIS SYSTEM.

This product design was developed over a number of years. We have purchased or

built virtually every binding/purfling gadget and tool out there including the one with the

router mounted on the sliding vertical stand. In our opinion none of them are very user

friendly. The inspiration for this machine came while observing the crafts persons at the

CF Martin Factory. These individuals effortlessly routed the top and back binding

rebates in just a few minutes. Although skilled, it was obvious that they did not have a

fear that their machines were going to initiate an improper cut. Also, they were in total

control of the process and the guitar body. The same is true of the operation at the

Taylor factory.

The following sets this machine apart from all others:

· Cost – Ours is reasonably affordable where as the complicated, not so user

friendly, West coast and Ohio style overhead machine with cutters is almost $700 and it

is still unable to cut custom grooves or handle slightly over or under size binding and

purflings!!!

· Router Bit – No fancy expensive bits or bearing size math calculations required!

All that is needed is a sharp 1/4" HSS (high speed steel) straight bit. Down-spiral bits

yield great results--- up-spiral bits or end mills are not recommended.

· Setup – Infinite height and depth adjustment in about 2 minutes – No Bit or

bearing changes – No carriage to adjust. We route D’s 000’s and J200 Jumbos using

the same bit settings. Simply put the body on the “GBC Shuttle” and start.

· Control – The cutting bit is directly in front of the operator and guitar is easily

and precisely guided on the platen using the “GBC Shuttle” The “GBC Shuttle” while

eloquently simple in design, provides for variable height. In addition it automatically and

gently handles tapered sides as well as top and back radius contours

· Quality – The captive bit feature virtually eliminates the possibility of damage

caused by presenting the body at the wrong angle to the bit or vise versa

· Dust Collection – We are not aware of any other machine with this feature.

Note: photos are file copies of our prototype machine.

The set up parameters are established using the actual binding and purfling materials

as gages. First step is to glue up a sample of the binding trim. In addition to providing

the exact thickness and height of material, the slight compensation for the glue line is

also inserted into the process.

as gages. First step is to glue up a sample of the binding trim. In addition to providing

the exact thickness and height of material, the slight compensation for the glue line is

also inserted into the process.

Use glue-ups like the ones above as gages to adjust the height and depth of the cut.

Height is set with the rack and pinion on the router and the Depth is set using the

Infinite Adjustment Sliding Guide.

Height is set with the rack and pinion on the router and the Depth is set using the

Infinite Adjustment Sliding Guide.

Place small piece of trim on the platen, raise the cutting edge of the bit flush with the

top of the sample

top of the sample

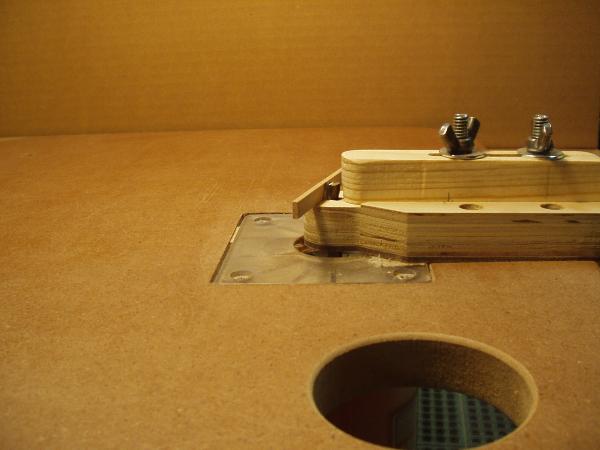

To set the depth, use a small piece of material as a stop block. Rotate the bit so the

tips of the cutting edges are parallel to the guide. Pinch the gage sample material

between the stop block and the guide tighten the wing nuts.

tips of the cutting edges are parallel to the guide. Pinch the gage sample material

between the stop block and the guide tighten the wing nuts.

After initial set-up, test the cut using pieces of scrap material, most likely fine

adjustment will be necessary. To aide in the fine tuning, mark a short continuous line on

the guide and slide base as illustrated below. This makes it easy to track the progress

of your fine adjustments.

adjustment will be necessary. To aide in the fine tuning, mark a short continuous line on

the guide and slide base as illustrated below. This makes it easy to track the progress

of your fine adjustments.

The KMG Binding Machine is the most user friendly device available,

however it is advised that you take time to make some practice cuts to get

familiar with the process before working on your guitar.

however it is advised that you take time to make some practice cuts to get

familiar with the process before working on your guitar.

When you have the proper tool, like our binding channel system, cutting rebates is not all

that difficult. However, realistically this process for many requires a completely new hand

eye coordination skill set. So like all other new motor skills it should be rehearsed. When it

is time to actually cut the channels on the prized instrument, the operator should be

comfortable in the knowledge that he understands what the router is about to do and that

he can control the tool to produce clean rebates in just a couple of passes. This is not a

simplistic approach ---- anything less is a “hope and a prayer” not craftsmanship.

that difficult. However, realistically this process for many requires a completely new hand

eye coordination skill set. So like all other new motor skills it should be rehearsed. When it

is time to actually cut the channels on the prized instrument, the operator should be

comfortable in the knowledge that he understands what the router is about to do and that

he can control the tool to produce clean rebates in just a couple of passes. This is not a

simplistic approach ---- anything less is a “hope and a prayer” not craftsmanship.

Practice cuts can be made using scrap material. Shape does not matter. Make cuts with

the grain, against the grain, on the edges, on the flat sides. Get the feel of starting the

cut. Stopping in the middle of a cut. Get comfortable holding and controlling the scrap

material, gliding the it over the table with the shuttle while positioning the edge on the

platen and against the guide. Developing this coordination simply improves productivity.

the grain, against the grain, on the edges, on the flat sides. Get the feel of starting the

cut. Stopping in the middle of a cut. Get comfortable holding and controlling the scrap

material, gliding the it over the table with the shuttle while positioning the edge on the

platen and against the guide. Developing this coordination simply improves productivity.

The “GBC” shuttle is placed on the

table – “green side up” than the guitar

is positioned on the shuttle. Note that in

the idle position, the guitar is above

and clear of the router bit. THIS FAIL

SAFE MODE OCCURS ANY TIME THE

BODY IS RELEASED --a good thing!

table – “green side up” than the guitar

is positioned on the shuttle. Note that in

the idle position, the guitar is above

and clear of the router bit. THIS FAIL

SAFE MODE OCCURS ANY TIME THE

BODY IS RELEASED --a good thing!

To make the actual cut simply place

the edge of the guitar body on the

platen and pull it into the bit. Think in

terms of routing “one inch at a time”

this is an important concept to

visualize. --With ANY routing tool

focus must be on the cutting bit.

Simply keep the edge flat on the platen

while feeding the body into the bit, this

is easy to do and becomes automatic

in a minute or two. Also, as the body is

moved along keep the chord of the

curve perpendicular the guide.

the edge of the guitar body on the

platen and pull it into the bit. Think in

terms of routing “one inch at a time”

this is an important concept to

visualize. --With ANY routing tool

focus must be on the cutting bit.

Simply keep the edge flat on the platen

while feeding the body into the bit, this

is easy to do and becomes automatic

in a minute or two. Also, as the body is

moved along keep the chord of the

curve perpendicular the guide.

Since about the only error that can

be made is a too shallow cut,

moving the body across the platen

and guide is a very quick process.

There is no fear of the dreaded

over cut or deep cut. Note that in our

shop we actually complete the channels

using three passes. A shallow cut, a

finish cut and finally a clean up cut,

paying close attention to carefully follow

the curves as described above.

be made is a too shallow cut,

moving the body across the platen

and guide is a very quick process.

There is no fear of the dreaded

over cut or deep cut. Note that in our

shop we actually complete the channels

using three passes. A shallow cut, a

finish cut and finally a clean up cut,

paying close attention to carefully follow

the curves as described above.

| Unlike other tools there is no balancing act needed to prevent damage!! |

The ability of the KMG Binding machine to easily cut the channels on the neck block

end of the body sets it apart from the others. When routing this area, continue to

keep the edge of the body positioned on the platen, in addition push down on the tail

block section. The unique design of the “GBC” shuttle allows the operator to change

attitude of the body so the edge at the neck block can be pulled tight into the guide

while flat on the platen

end of the body sets it apart from the others. When routing this area, continue to

keep the edge of the body positioned on the platen, in addition push down on the tail

block section. The unique design of the “GBC” shuttle allows the operator to change

attitude of the body so the edge at the neck block can be pulled tight into the guide

while flat on the platen

The KMG Binding Machine as shipped usually has sufficient slope sanded on the front

edge of the platen to allow the body to be tilted and pulled tight against the guide. If

additional clearance is needed, use sand paper or a file to increase the slope angle on

the end of the guide. Work slowly, only making small changes; check your work as you

go. The idea is to keep as much of the platen flat as possible.

edge of the platen to allow the body to be tilted and pulled tight against the guide. If

additional clearance is needed, use sand paper or a file to increase the slope angle on

the end of the guide. Work slowly, only making small changes; check your work as you

go. The idea is to keep as much of the platen flat as possible.

| WHY IT WORKS!! |

A hand held router must be guided

along the side of the guitar. There are

a few router attachments available that

facilitate this action. The problem is,

even with those devices there is a risk

of tipping the router, which will result in

a channel that is too deep and too

wide on the top or back.

along the side of the guitar. There are

a few router attachments available that

facilitate this action. The problem is,

even with those devices there is a risk

of tipping the router, which will result in

a channel that is too deep and too

wide on the top or back.

Remove the sliding guide and place

three small 1/4" id washers on each

bolt. Install the guide on top of the

washers.

three small 1/4" id washers on each

bolt. Install the guide on top of the

washers.

Note the gap that is formed between

the bottom of the guide and the top of

the platen.

the bottom of the guide and the top of

the platen.

Raise the bit just slightly higher then

the bottom of the sliding guide. Adjust

the sliding guide flush with the bit's

cutting edge. With this set-up the side

rides on the guide but the over hang

fits in the gap and will be trimmed flush

to the side.

the bottom of the sliding guide. Adjust

the sliding guide flush with the bit's

cutting edge. With this set-up the side

rides on the guide but the over hang

fits in the gap and will be trimmed flush

to the side.

The components for the Channel routing system are precision CNC machined in our

shop. By design the table is meant to be fastened to a workbench using two screws. We

have found this to be an ideal working height in addition to providing a compact space

saving configuration. The vacuum port is the standard 2 ¼” diameter.

shop. By design the table is meant to be fastened to a workbench using two screws. We

have found this to be an ideal working height in addition to providing a compact space

saving configuration. The vacuum port is the standard 2 ¼” diameter.

The guidance scheme on the KMG Binding System works differently. The sides and the

Top or Back of the body are used to regulate the height and depth of the channels.

The adjustable guide and the platen form a wedge shape/corner. The matching edge of

the body is simply moved across the wedge – in fact, care must be taken to make sure

the channel is cut the entire height and depth. As illustrated below even if the body

contacts the bit at steep angle off the table only a minor error would occur.

Top or Back of the body are used to regulate the height and depth of the channels.

The adjustable guide and the platen form a wedge shape/corner. The matching edge of

the body is simply moved across the wedge – in fact, care must be taken to make sure

the channel is cut the entire height and depth. As illustrated below even if the body

contacts the bit at steep angle off the table only a minor error would occur.

| BONUS FEATURE A two minute modification converts the unit into a precision Top and Back overhang trimmer |

If it occurred to you that the hobby tower and articulating monster binding

machines may be built up-side down you are correct -- that is why you'll never

see those gadgets in a factory tour video. Like KMG those seeking high

quality and efficiency keep it simple --- read on!

machines may be built up-side down you are correct -- that is why you'll never

see those gadgets in a factory tour video. Like KMG those seeking high

quality and efficiency keep it simple --- read on!