Kenneth Michael Guitars est.1978

| Fret Dressing using "Essential tools" that don't break the bank |

Fret dressing is a little easier if it can

be preformed before the neck is

assembled to the body. It is important

the truss rod is adjusted so the neck is

perfectly flat --- check that by looking

down the edge of the fingerboard.

be preformed before the neck is

assembled to the body. It is important

the truss rod is adjusted so the neck is

perfectly flat --- check that by looking

down the edge of the fingerboard.

Gently glide 12” long sanding block

(220 grit) along the tops of the frets

one or two times, at this point we are

checking for high frets. If a fret is high

it is easy to spot because it will now

have a flat spot on the top edge.

Double check to make sure that the

high frets found are properly seated by

tapping them down with your fretting

hammer.

(220 grit) along the tops of the frets

one or two times, at this point we are

checking for high frets. If a fret is high

it is easy to spot because it will now

have a flat spot on the top edge.

Double check to make sure that the

high frets found are properly seated by

tapping them down with your fretting

hammer.

Using the 30-degree file block dress

off the end of the frets on each side of

the fingerboard. This process leaves a

razor sharp edge on both sides of

every fret.

off the end of the frets on each side of

the fingerboard. This process leaves a

razor sharp edge on both sides of

every fret.

Again, gently glide the 12” sanding

block across the tops of the frets, this

time use several passes. The object is

to make sure each fret is the same

height and level with its neighbor.

There will be a trace of silver dust on

each side of every fret and a narrow

flat spot along the full length of each

fret.

block across the tops of the frets, this

time use several passes. The object is

to make sure each fret is the same

height and level with its neighbor.

There will be a trace of silver dust on

each side of every fret and a narrow

flat spot along the full length of each

fret.

Use the crowning tool with high quality

220 grit “wet or dry” sand paper to

reshape the tops of each fret. Take

care to stay on the fret prevent

scratching the surface of the

fingerboard.

220 grit “wet or dry” sand paper to

reshape the tops of each fret. Take

care to stay on the fret prevent

scratching the surface of the

fingerboard.

The sharp edges of the fret ends are

removed using the reworked triangular

file. Place the file at a slight angle up

against the fret, with the smooth corner

on the fingerboard. Knock off the

pointed edge with a push and roll

motion that slightly rounds over the fret

ends. Repeat the process on both

sides of all the frets. Carefully, test the

fret end with your fingertip.

removed using the reworked triangular

file. Place the file at a slight angle up

against the fret, with the smooth corner

on the fingerboard. Knock off the

pointed edge with a push and roll

motion that slightly rounds over the fret

ends. Repeat the process on both

sides of all the frets. Carefully, test the

fret end with your fingertip.

Burnish each fret progressing through

320 – 400 grit “wet or dry” sand paper.

320 – 400 grit “wet or dry” sand paper.

Major scratches are removed from the

fingerboard using a single edge razor

blade as scraper blade. Move the

blade back and forth between the frets

in a perpendicular motion taking care

not to dig into the surface – a smooth

gentle action will produce very fine

even shavings. The procedure is much

easier than it sounds.

fingerboard using a single edge razor

blade as scraper blade. Move the

blade back and forth between the frets

in a perpendicular motion taking care

not to dig into the surface – a smooth

gentle action will produce very fine

even shavings. The procedure is much

easier than it sounds.

Use a very small block and sand between each fret in a perpendicular motion working

progressively through 220 – 320 – 400 – 600 “wet or dry” sandpaper. Take care not

to scratch the frets.

progressively through 220 – 320 – 400 – 600 “wet or dry” sandpaper. Take care not

to scratch the frets.

Burnish each fret with 600 grit “wet or

dry” sand paper.

dry” sand paper.

Rub down the entire fingerboard with 0000 steel wool, apply a coat of paste wax, and

let it dry. Very carefully burnish each fret with 600 grit paper and finally, buff out the

coat of wax. The fingerboard will be smooth as glass and the frets will sparkle.

let it dry. Very carefully burnish each fret with 600 grit paper and finally, buff out the

coat of wax. The fingerboard will be smooth as glass and the frets will sparkle.

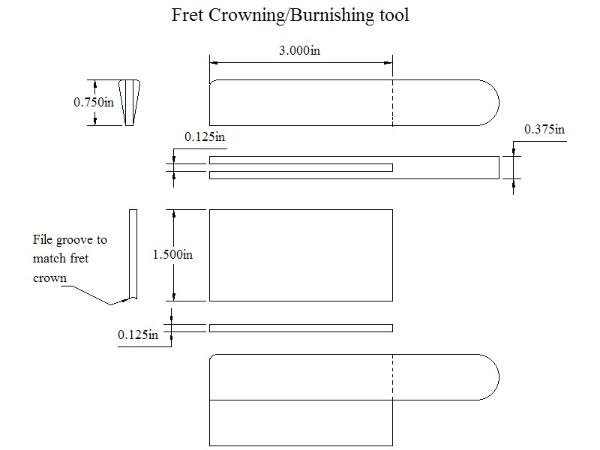

This is a version of the “Don Teeter” Burnishing tool. It is made using scraps of

hardwood. Cut the two components with the grain going lengthwise. Cut the slot in

the handle on a table saw. An alternate method of assembly would be a three-

piece sandwich. The fret crowning groove is made with a small round file. A ball

end bit mounted in a Dremel with a router base will also work well. Test the groove

against the fret wire that is used.

hardwood. Cut the two components with the grain going lengthwise. Cut the slot in

the handle on a table saw. An alternate method of assembly would be a three-

piece sandwich. The fret crowning groove is made with a small round file. A ball

end bit mounted in a Dremel with a router base will also work well. Test the groove

against the fret wire that is used.

It is important that high quality “wet or

dry” sandpaper is used.

220,320,400,600 grits cut into 3” strips

dry” sandpaper is used.

220,320,400,600 grits cut into 3” strips

A “Fret End” file block can be

fashioned from a 2”x 6” piece of MDF,

hardwood or softwood. One edge is

cut at a 30-degree angle. Three wood

screws with washers are used to fasten

a small smooth file to the angled edge

of the block. For a little extra stability

hot melt glue was added along the

length of the file.

fashioned from a 2”x 6” piece of MDF,

hardwood or softwood. One edge is

cut at a 30-degree angle. Three wood

screws with washers are used to fasten

a small smooth file to the angled edge

of the block. For a little extra stability

hot melt glue was added along the

length of the file.

A special file is needed to refine the

shape of the frets without damaging

the fingerboard in the process. Not

surprisingly, such a tool can be seen

at the Martin factory. It is simply a fine

6” triangular file with the three corners

ground to a small flat. This

configuration allows the file to move

along the fingerboard surface while the

cutting edges contact the frets.

shape of the frets without damaging

the fingerboard in the process. Not

surprisingly, such a tool can be seen

at the Martin factory. It is simply a fine

6” triangular file with the three corners

ground to a small flat. This

configuration allows the file to move

along the fingerboard surface while the

cutting edges contact the frets.