Kenneth Michael Guitars est.1978

KMG "Success Kit"

| The Compensated Saddle |

There is really no reason to get all tense and confused when the conversation regarding the

“compensated saddle” or “intonation” is in the forefront. Compensating the saddle and for that

matter the saddle location and angle to the frets is an adjustment that is necessary because

the fretting action increases tension, raises the pitch slightly. Actually, the sounding side of the

string is too short to work with the purely mathematical spacing of the frets and saddle. So we

COMPENSATE by moving the bridge/saddle back away from the 12th fret. In a perfect world

the 12th fret defines the center of the scale length, if we could disregard the physical

characteristics of the string material and flexing action, the saddle would be placed at the same

distance from the 12th fret as the front edge of the nut to the 12th fret ----- but we can’t so

here is how we address the issue.

The “KMG Bridge setter” that came with your complete “Success Kit Package” will automatically

place the saddle and bridge in a location that is a very good starting position when it is time to

“tweak” the individual string lengths for optimal musical accuracy. – INTONATION.

The truth is – the time to set the intonation on a newly built instrument is not the day the

strings are installed for the first time. The guitar needs time to acclimate to the stress from the

strings and it’s environment. Final, truss rod adjustment, action and maybe most importantly

the preferred string type, gage and brand need to be determined. Note that the full potential of

a guitar cannot be found if you simply install a popular brand of strings, experimentation will

often be well rewarded.

What we do know about any given set of strings is that compensation requirements are not

based on the overall diameter of the string but rather the diameter of the “core”. Again, in that

perfect world scenario one would think that since the 1st string is the highest pitch and the 6th

sting is the lowest we should be able to move the saddle back from the 12th fret at an angle

and bingo – we could take into account the various string gages. But the real world issue of

“core diameter” dictates that we COMPENSATE for the disproportionate core diameter

sequence.

In other words the 2nd string is thicker than the “core” of 3rd string and in many sets also

thicker than the “core” of the 4th, so just using a slanted saddle will not get the job done.

“compensated saddle” or “intonation” is in the forefront. Compensating the saddle and for that

matter the saddle location and angle to the frets is an adjustment that is necessary because

the fretting action increases tension, raises the pitch slightly. Actually, the sounding side of the

string is too short to work with the purely mathematical spacing of the frets and saddle. So we

COMPENSATE by moving the bridge/saddle back away from the 12th fret. In a perfect world

the 12th fret defines the center of the scale length, if we could disregard the physical

characteristics of the string material and flexing action, the saddle would be placed at the same

distance from the 12th fret as the front edge of the nut to the 12th fret ----- but we can’t so

here is how we address the issue.

The “KMG Bridge setter” that came with your complete “Success Kit Package” will automatically

place the saddle and bridge in a location that is a very good starting position when it is time to

“tweak” the individual string lengths for optimal musical accuracy. – INTONATION.

The truth is – the time to set the intonation on a newly built instrument is not the day the

strings are installed for the first time. The guitar needs time to acclimate to the stress from the

strings and it’s environment. Final, truss rod adjustment, action and maybe most importantly

the preferred string type, gage and brand need to be determined. Note that the full potential of

a guitar cannot be found if you simply install a popular brand of strings, experimentation will

often be well rewarded.

What we do know about any given set of strings is that compensation requirements are not

based on the overall diameter of the string but rather the diameter of the “core”. Again, in that

perfect world scenario one would think that since the 1st string is the highest pitch and the 6th

sting is the lowest we should be able to move the saddle back from the 12th fret at an angle

and bingo – we could take into account the various string gages. But the real world issue of

“core diameter” dictates that we COMPENSATE for the disproportionate core diameter

sequence.

In other words the 2nd string is thicker than the “core” of 3rd string and in many sets also

thicker than the “core” of the 4th, so just using a slanted saddle will not get the job done.

Prepare the saddle blank by cutting it to length, take care not to make it too short. Use a

sanding stick to gently round the edges of both ends.

sanding stick to gently round the edges of both ends.

The saddle needs to fit snug in the slot --- most likely the blank provided will be a tad too

thick for the bridge slot. Carefully thin the blank by sliding it on a flat sanding block or stick.

Many find wearing rubber gloves, a rubber finger or wrapping tape around the fingers

provides a little traction to help move the saddle against the abrasive surface.

thick for the bridge slot. Carefully thin the blank by sliding it on a flat sanding block or stick.

Many find wearing rubber gloves, a rubber finger or wrapping tape around the fingers

provides a little traction to help move the saddle against the abrasive surface.

Next use a compass to define the top of the saddle and establish the radius to match the

fingerboard.

fingerboard.

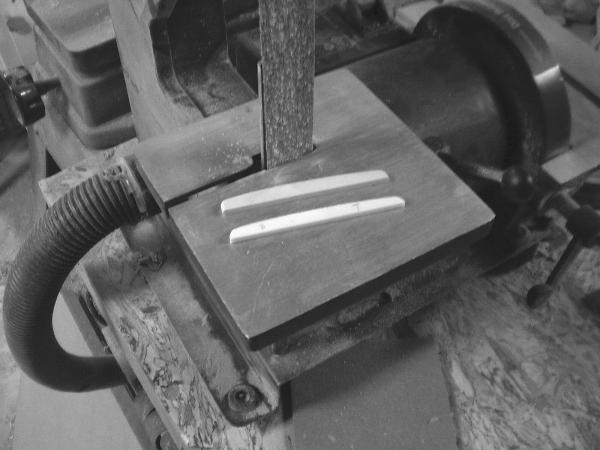

The tool of choice for shaping the saddle would be some sort of belt sander. Files and

sanding sticks can also be used and yield good results

sanding sticks can also be used and yield good results

For the preliminary set-up its not necessary to

be extremely precise. As mentioned early on,

the guitar needs to "settle in" before the micro

measurements will really matter. For now

shape the top of the saddle as illustrated. Note

the top edge at the 1st sting contact point is

well to the front (toward the nut) the 2nd string

is well toward the back, and the remaining four

string contact points are simply angled from

front to back the remaining length of the

saddle.

be extremely precise. As mentioned early on,

the guitar needs to "settle in" before the micro

measurements will really matter. For now

shape the top of the saddle as illustrated. Note

the top edge at the 1st sting contact point is

well to the front (toward the nut) the 2nd string

is well toward the back, and the remaining four

string contact points are simply angled from

front to back the remaining length of the

saddle.

The string contact surface should be smooth and slightly rounded --- we need to prevent

binding or the chance of breakage due to a sharp edge

binding or the chance of breakage due to a sharp edge

Now you can finally install the strings ---- no doubt the action will be very high. Set the truss

rod adjustment nut so that there is just a tiny bit of tension, then bring the tuning up to pitch.

It is best if you allow the string tension to exert force on the neck for awhile before

proceeding. After a few hours look down the neck from the nut end to see if the fingerboard

straight. Adjust the truss rod if necessary to take out any bow. Loosen the strings turn the

nut a small amount (no more than a 1/4 turn) -- bring the tuning up to pitch once again.

Repeat as necessary to get the neck straight as possible.

rod adjustment nut so that there is just a tiny bit of tension, then bring the tuning up to pitch.

It is best if you allow the string tension to exert force on the neck for awhile before

proceeding. After a few hours look down the neck from the nut end to see if the fingerboard

straight. Adjust the truss rod if necessary to take out any bow. Loosen the strings turn the

nut a small amount (no more than a 1/4 turn) -- bring the tuning up to pitch once again.

Repeat as necessary to get the neck straight as possible.

Take a measurement at the 12th fret 1st and 6th strings. Feeler gages work well for this

purpose. Ideally we want to end up with a measurement of .070" from the top of the fret to

the bottom of the high "E" 1st string and .085" from the top of the fret to the bottom of the

low "E" 6th string. In all probability the bottom of the saddle will need to be shaved to get the

height/action correct.

purpose. Ideally we want to end up with a measurement of .070" from the top of the fret to

the bottom of the high "E" 1st string and .085" from the top of the fret to the bottom of the

low "E" 6th string. In all probability the bottom of the saddle will need to be shaved to get the

height/action correct.

Now loosen the strings and remove the saddle, in some instances removing the bridge pins

may also be necessary. If that is the case I found it is helpful to tape the strings to an index

card this procedure keeps the strings under control. One of those big "snack bag clips" works

too.

may also be necessary. If that is the case I found it is helpful to tape the strings to an index

card this procedure keeps the strings under control. One of those big "snack bag clips" works

too.

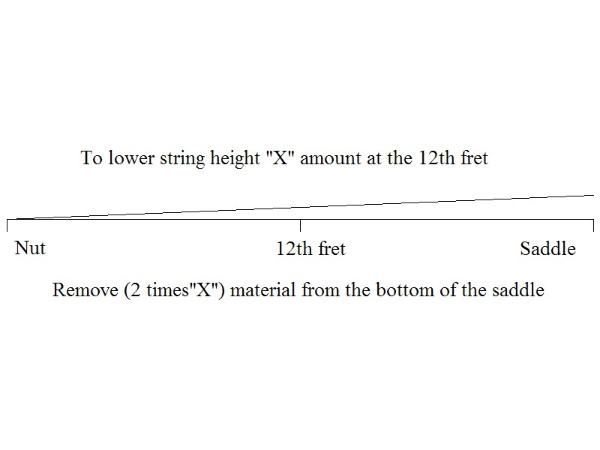

The math calculation for establishing the saddle height is straight forward, as illustrated

below

below

Since the 12th fret essentially falls in the center of the triangle formed by the fingerboard and

saddle. The simple 2 to 1 ratio works out almost perfect and is precise enough for our purpose.

saddle. The simple 2 to 1 ratio works out almost perfect and is precise enough for our purpose.

As an example -- the measurement taken from the 1st sting is .100" (.100" -.070") .03" too

high so we need to remove .060" ( 2 x .03") from the bottom of the saddle at the 1st string

cross over location. The measurement from the 6th string is .110" (.110 - .085") .025" too

high. Again we need to remove .050" (2 x .025") from the bottom of the saddle at the 6th

string cross over location.

high so we need to remove .060" ( 2 x .03") from the bottom of the saddle at the 1st string

cross over location. The measurement from the 6th string is .110" (.110 - .085") .025" too

high. Again we need to remove .050" (2 x .025") from the bottom of the saddle at the 6th

string cross over location.

Plot the cut off line on the blank. A belt sander can be used to remove the bulk of material.

However, this surface "must be" perfectly flat with the bottom perpendicular to the sides.

Make no mistake -- a sloppy job -- will no doubt have a huge effect on sound quality. This is

it "where the rubber hits the road" so to speak. We want to establish the best possible link

between the strings, saddle, bridge and soundboard.

However, this surface "must be" perfectly flat with the bottom perpendicular to the sides.

Make no mistake -- a sloppy job -- will no doubt have a huge effect on sound quality. This is

it "where the rubber hits the road" so to speak. We want to establish the best possible link

between the strings, saddle, bridge and soundboard.

When you are satisfied replace the saddle, string up, tune up and check out the action and

playability of the instrument. If you followed the "Zero - Zero Fret nut making guide" and now

have the saddle at a good height, action and intonation should be at respectable levels.

After a period of time the action may get a little high again -- check the neck for bowing an if

necessary tweak the truss rod nut to adjust. One last thing at this point --- for the lowest

possible action it is necessary to have "relief" in the neck --- or more simply put -- allow the

neck to bow a very tiny bit. Since the strings vibrate in a 360 degree pattern the slight bow in

the neck provides some additional clearance for the movement of the pluck string.

playability of the instrument. If you followed the "Zero - Zero Fret nut making guide" and now

have the saddle at a good height, action and intonation should be at respectable levels.

After a period of time the action may get a little high again -- check the neck for bowing an if

necessary tweak the truss rod nut to adjust. One last thing at this point --- for the lowest

possible action it is necessary to have "relief" in the neck --- or more simply put -- allow the

neck to bow a very tiny bit. Since the strings vibrate in a 360 degree pattern the slight bow in

the neck provides some additional clearance for the movement of the pluck string.

Intonation and fine tuning the set up will be covered elsewhere.