Kenneth Michael Guitars est.1978

| KMG "Success Kit" Neck Prep & Assembly |

Depending on the specific kit package

KMG neck will come with tuning machine

holes pre-drilled, or must be marked and

pre-drilled using the supplied template.

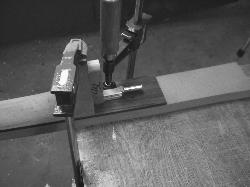

The KMG tuning machines supplied

require a 10mm (.390”) mounting hole. It

is best use a drill press and drill from the

veneer side of the peg head. A backer

board should be securely taped to the

back of the peg head to help prevent chip

out. It is best to drill to final size using

progressively larger diameter bits.

This will minimize chance of

wandering off location

KMG neck will come with tuning machine

holes pre-drilled, or must be marked and

pre-drilled using the supplied template.

The KMG tuning machines supplied

require a 10mm (.390”) mounting hole. It

is best use a drill press and drill from the

veneer side of the peg head. A backer

board should be securely taped to the

back of the peg head to help prevent chip

out. It is best to drill to final size using

progressively larger diameter bits.

This will minimize chance of

wandering off location

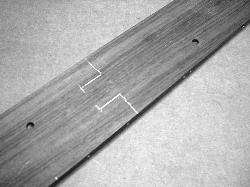

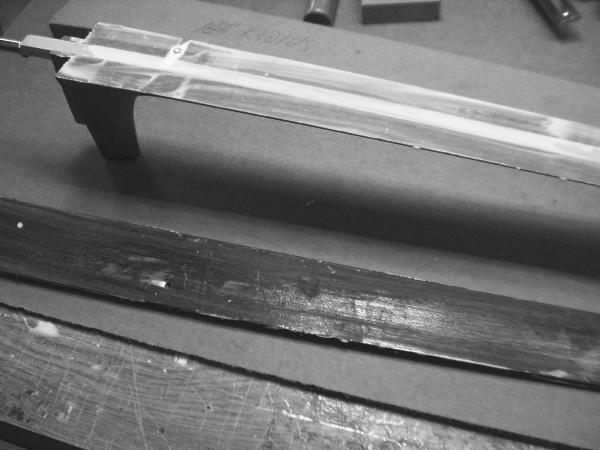

Prior to gluing the truss rod in place it

recommended that a mark is placed

on the neck to indicate the proper

clearance in the neck slot – if the rod

is too far toward the peg head it can

ride up on the slot channel and will

not be at the correct level.

recommended that a mark is placed

on the neck to indicate the proper

clearance in the neck slot – if the rod

is too far toward the peg head it can

ride up on the slot channel and will

not be at the correct level.

Some builders do not glue the truss rod in the belief that tension alone will prevent

movement. Just as a measure of insurance I recommend an application of Titebond to

keep things tight and stable this in turn helps in the prevention of buzz and rattles. Do not

get any glue on the paper covering – note that the paper side goes down into the slot.

movement. Just as a measure of insurance I recommend an application of Titebond to

keep things tight and stable this in turn helps in the prevention of buzz and rattles. Do not

get any glue on the paper covering – note that the paper side goes down into the slot.

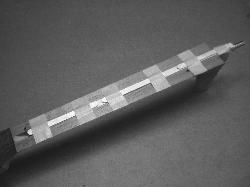

The veneer filler is now glued to the to of the truss rod. Apply a thin layer of Titebond,

position the filler, craft sticks and masking tape can be used to hold the filler in lace until

dry.

position the filler, craft sticks and masking tape can be used to hold the filler in lace until

dry.

Once the glue dries use a scraper

blade to level the filler to the

fingerboard surface. This is a very

important step – a high spot will cause

mis-alignment when gluing the

fingerboard to the neck.

blade to level the filler to the

fingerboard surface. This is a very

important step – a high spot will cause

mis-alignment when gluing the

fingerboard to the neck.

Since the glue we are using has a high percentage of water, care must to taken to

apply a balanced amount of the product. Our aim is a good bond without the worry of

warping the neck or fingerboard. There is no need to apply glue to the fingerboard

extension. Mark off this area.

apply a balanced amount of the product. Our aim is a good bond without the worry of

warping the neck or fingerboard. There is no need to apply glue to the fingerboard

extension. Mark off this area.

Guidelines in place

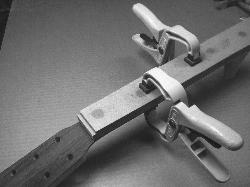

Apply several layers of 1/2" wide tape

along the edges of the finger-board caul,

this build up will serve to form a

contoured surface which will help to

compress the FB against the neck more

uniformly. As with all gluing operations

make a test run of the clamping set up.

Note the use of the contoured cauls on

the neck and the fingerboard.

along the edges of the finger-board caul,

this build up will serve to form a

contoured surface which will help to

compress the FB against the neck more

uniformly. As with all gluing operations

make a test run of the clamping set up.

Note the use of the contoured cauls on

the neck and the fingerboard.

Carefully apply a THIN layer of glue to the neck surface and the finger. Position the

fingerboard and apply the clamps. Clean up as much of the glue squeeze as possible

with out disturbing the clamps

fingerboard and apply the clamps. Clean up as much of the glue squeeze as possible

with out disturbing the clamps

It is best to let this assembly dry

overnight to allow the components to

stabilize

overnight to allow the components to

stabilize

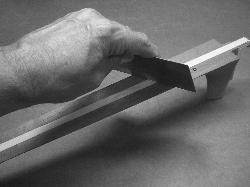

The fingerboard-clamping caul is a multi-tasking device, now we are going to use it to

support the neck assembly for final shaping. I have found that using a corner of the

workbench is a good location to set up the shaping operation. Align the caul (support) in

such a way so it is clear of the edge of the fingerboard.

support the neck assembly for final shaping. I have found that using a corner of the

workbench is a good location to set up the shaping operation. Align the caul (support) in

such a way so it is clear of the edge of the fingerboard.

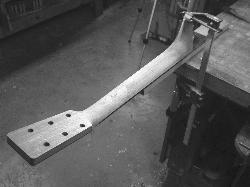

Emery cloth is the best abrasive to use for the neck shaping procedure. It is more

durable than regular sand paper. If Emery is unavailable to you, paper backed sand

paper can be reinforced using duct or packaging tape. To prevent deep scratches the

shaping should be done with nothing less than 150 grit. There is no magic formula for

this process --- without sounding like a smart a** --- you need to sand away everything

that does not look or feel like a guitar neck. Use a guitar with a neck you like as a

model, work slowly. Sanding cross grain is more aggressive but leaves more scratches.

When properly executed the edge of the fingerboard actually takes on a slight

curvature, which in turn unifies the two pieces.

durable than regular sand paper. If Emery is unavailable to you, paper backed sand

paper can be reinforced using duct or packaging tape. To prevent deep scratches the

shaping should be done with nothing less than 150 grit. There is no magic formula for

this process --- without sounding like a smart a** --- you need to sand away everything

that does not look or feel like a guitar neck. Use a guitar with a neck you like as a

model, work slowly. Sanding cross grain is more aggressive but leaves more scratches.

When properly executed the edge of the fingerboard actually takes on a slight

curvature, which in turn unifies the two pieces.

When you are satisfied with the look and feel of the arm portion, reposition and

re-clamp the assembly so you can access the heel. Take care not to remove too much

material and work to keep both sides symmetrical.

re-clamp the assembly so you can access the heel. Take care not to remove too much

material and work to keep both sides symmetrical.

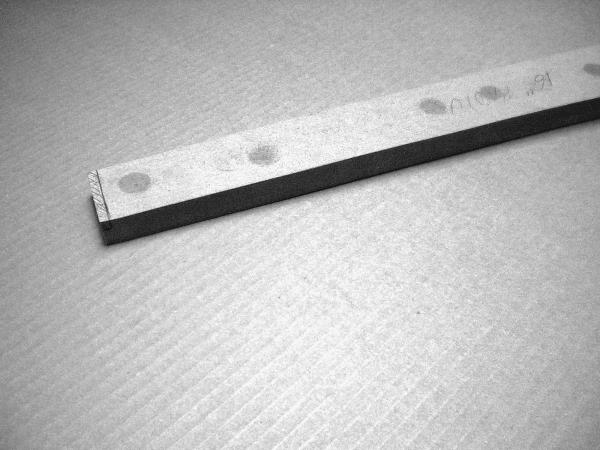

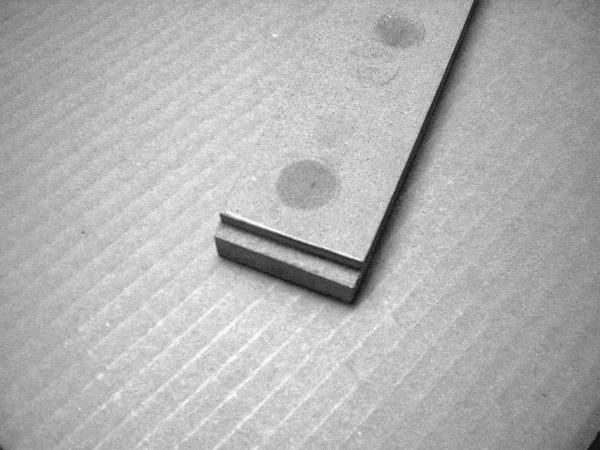

More multi-tasking for the fingerboard caul --- the caul will now be used as a straight

edge, saw guide to trim the head stock veneer at the proper angle. The photos below

illustrate how to notch the topside of the caul to allow clearance for the spine of the razor

saw.

edge, saw guide to trim the head stock veneer at the proper angle. The photos below

illustrate how to notch the topside of the caul to allow clearance for the spine of the razor

saw.

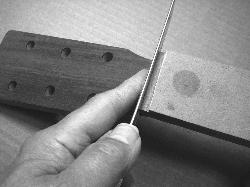

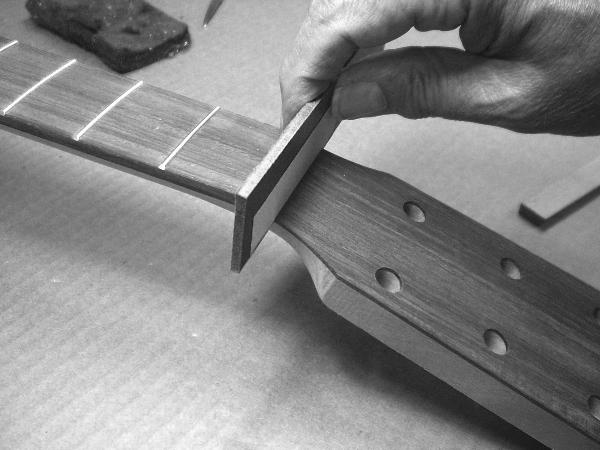

In preparation to trim the headstock veneer aligning the nut against the end of the

fingerboard than carefully draw a line on the veneer. The caul is then lined up above the

mark.

fingerboard than carefully draw a line on the veneer. The caul is then lined up above the

mark.

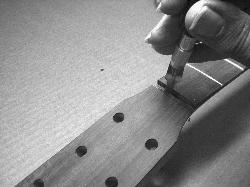

Note that this set-up allows a cut that is

perpendicular and parallel to the end

of the fingerboard. The notch in the

caul provides the clearance so that the

spine of the razor saw does not

contact the guiding edge.

perpendicular and parallel to the end

of the fingerboard. The notch in the

caul provides the clearance so that the

spine of the razor saw does not

contact the guiding edge.

Holding the razor saw tight against the guide saw through the headstock veneer being

careful not to cut into the neck.

careful not to cut into the neck.

Use a utility or Exacto knife to carefully separate the cutoff section of veneer from the

neck at each side of the headstock. Use a small chisel to clear the cutoff from the nut

slot.

neck at each side of the headstock. Use a small chisel to clear the cutoff from the nut

slot.

To add refinement to the nut slot two special sanding sticks are made. One is the

exact width of the nut and has sand paper glue to the bottom. The second stick is

made of ¾” x 1/8” Masonite and has sand paper glue to wide side.

exact width of the nut and has sand paper glue to the bottom. The second stick is

made of ¾” x 1/8” Masonite and has sand paper glue to wide side.

| Carefully smooth the bottom of the nut slot |

| Using the 1/8" thick sanding stick smooth the edge of the veneer |

| The nut should fit snug in the slot with no tendencies to tilt or rock in any direction |

The fingerboard extension needs to be trimmed to match the sound hole. Using the

supplied fasteners secure the neck assembly to the body. Mark the bottom of the

fingerboard where it intersects the sound hole.

supplied fasteners secure the neck assembly to the body. Mark the bottom of the

fingerboard where it intersects the sound hole.

Use a compass to draw a line along the edge of the fingerboard extension. The

compass is set to the mark previously made plus approximately 1/16”. This will result in

a slight reveal between the sound hole and the end of the fingerboard. Generally, the

reveal is held shy of the rosette and this is our preference as well.

compass is set to the mark previously made plus approximately 1/16”. This will result in

a slight reveal between the sound hole and the end of the fingerboard. Generally, the

reveal is held shy of the rosette and this is our preference as well.

| Double-check your measurements, than carefully cut of the fingerboard along the line. |

| Finally, sand the end of the fingerboard to form a gentle radius. |

Go HERE first ----- Tenon end of the neck needs some fine tuning before gluing

on the fingerboard --- click on this message

on the fingerboard --- click on this message

Now - before attaching the

fingerboard to the neck -- is a

good time to prepare the neck

heel and cheek perimeter

surface. Go HERE to find out

how to do it and why it must be

done.

fingerboard to the neck -- is a

good time to prepare the neck

heel and cheek perimeter

surface. Go HERE to find out

how to do it and why it must be

done.

The fingerboard is positioned on the neck with the center of the 12th

or 14th fret slot on the body/neck joint. Take care to center the board

on the neck (KMG necks are left over-size to allow for different FB

width preferences.) Once in the proper position, clamp/tape the

finger-board to the neck. Drill two #54 size holes into the neck through

the 3rd and 13th (or 11th) fret slots. Insert #18 brads in the holes keep

the FB in the proper position. Remember that frets for these two slots

are install AFTER the fingerboard is glued to the neck

or 14th fret slot on the body/neck joint. Take care to center the board

on the neck (KMG necks are left over-size to allow for different FB

width preferences.) Once in the proper position, clamp/tape the

finger-board to the neck. Drill two #54 size holes into the neck through

the 3rd and 13th (or 11th) fret slots. Insert #18 brads in the holes keep

the FB in the proper position. Remember that frets for these two slots

are install AFTER the fingerboard is glued to the neck